|

HOME || PROFILE || PRODUCTS || OUR CLIENTAL || CONTACT US |

|

|

|

|

|

|

|

|

HOME || PROFILE || PRODUCTS || OUR CLIENTAL || CONTACT US |

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

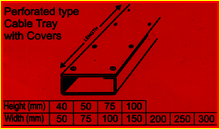

Perforated

Type Cable Trays are used for laying of Instrumentation, Control & Power

Cables. These cable trays provide excellent ventilation & protect the

cables.

Material used for fabrication of Perforated

Type Cable Tray:

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

Perforated Type Cable Tray Accessories |

||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

Horizontal Cross Tees Reducers |

||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

GALVANIZING Corrosion is destructive result of the chemical action between metal and its environment; it is the process of metal being worn away. the most durable way to protect steel is Hot Dip Galvanizing. The Zinc coating protects the surface against corrosion by providing protection to the iron or steel in the following ways; it shields the base metal from the atmosphere. Smooth and high quality coating even on awkward and intricate surfaces. Equally good coating on sharp edges and corners. Further maintenance on site is rarely demanded. Hot Dip Galvanizing after fabrication is done as per I.S;269; 1985 & 4759; Special High Grade Zinc of 99.995% purity is used. COATING REQUIREMENT Mass of Zinc Coating- Requirement for the mass of zinc coating as per is for different classes of materials are given below. |

||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

Tel:+91 7714050653[O], +91 9893350653, Email: madhurengineering@rediffmail.com |

|

|

HOME || PROFILE || PRODUCTS || OUR CLIENTLE || CONTACT US |

|

Copyright © 2006-07 Madhur Engineering Works. All Right Reserved. |

|